Production

3D printing, also known as additive manufacturing, is the technology that has fundamentally changed the way we make things. With 3D printing, we can build physical objects layer by layer, based on 3D digital models. This enables not only rapid prototyping, but also the production of highly complex parts and products with unprecedented precision.

The layer-by-layer production method is proving to be a highly innovative technology making it possible to produce complex objects with remarkable efficiency and flexibility. Compared to conventional manufacturing processes, 3D printing offers decisive advantages such as cost-effective production of one-off prototypes and small batches without the need for expensive tooling or molds. Not only does this significantly reduce lead times, but it also allows parts to be customized to meet specific requirements.

Additive manufacturing minimizes material waste by processing only the amount of material that the component will actually need in the end. This promotes sustainability and opens up a wide range of applications, from creative design to manufacturing replacement parts.

Whether in industry, healthcare, architecture or arts and crafts, additive manufacturing opens up countless possibilities for creative innovation and customized solutions. Welcome to the future of manufacturing - welcome to the world of 3D printing.

Fused Filament Fabrication

A 3D-printing method suited for cost-efficient prototyping and series parts.

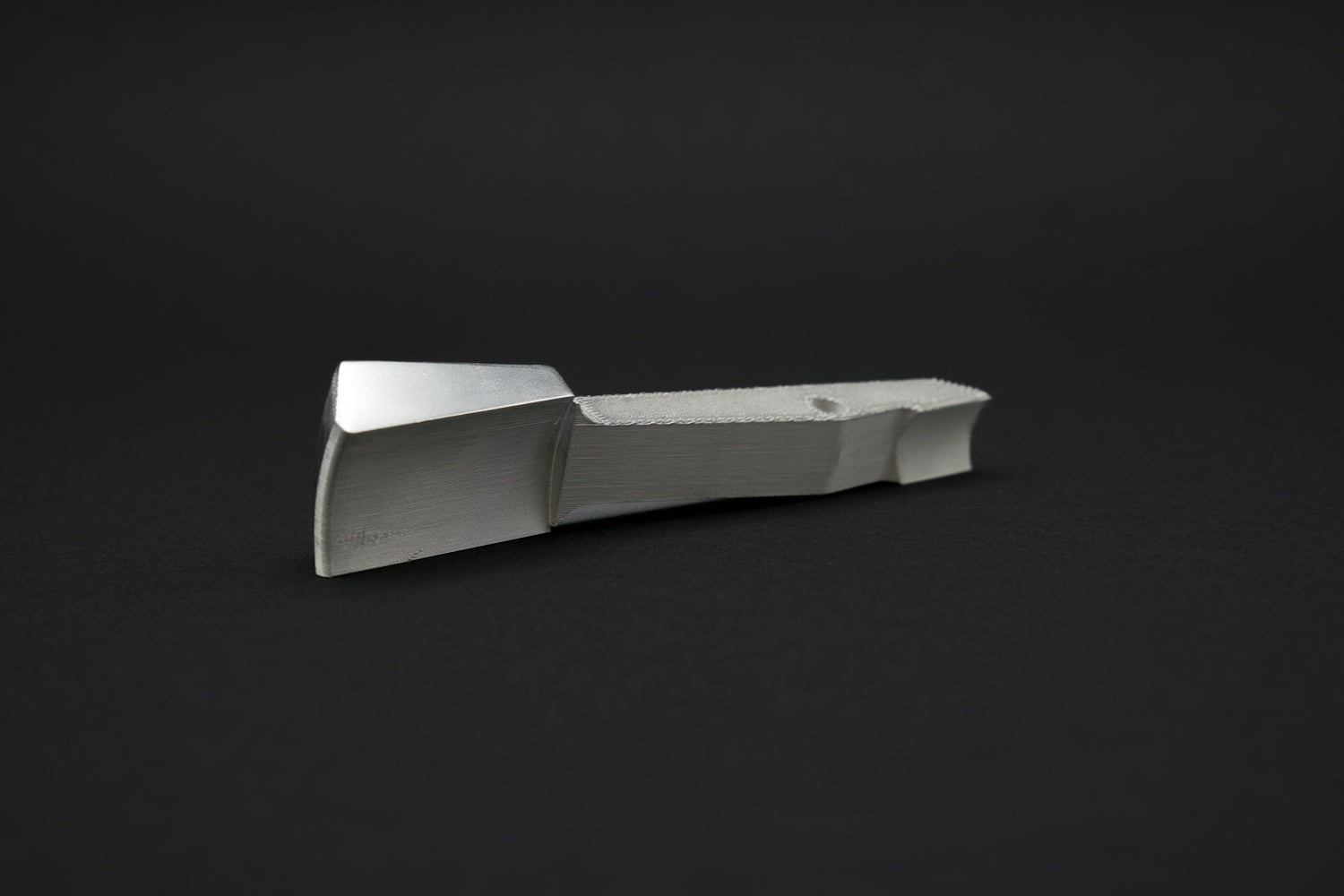

Selective Laser Melting

A powder based 3D-printing method to produce end-use metal parts.

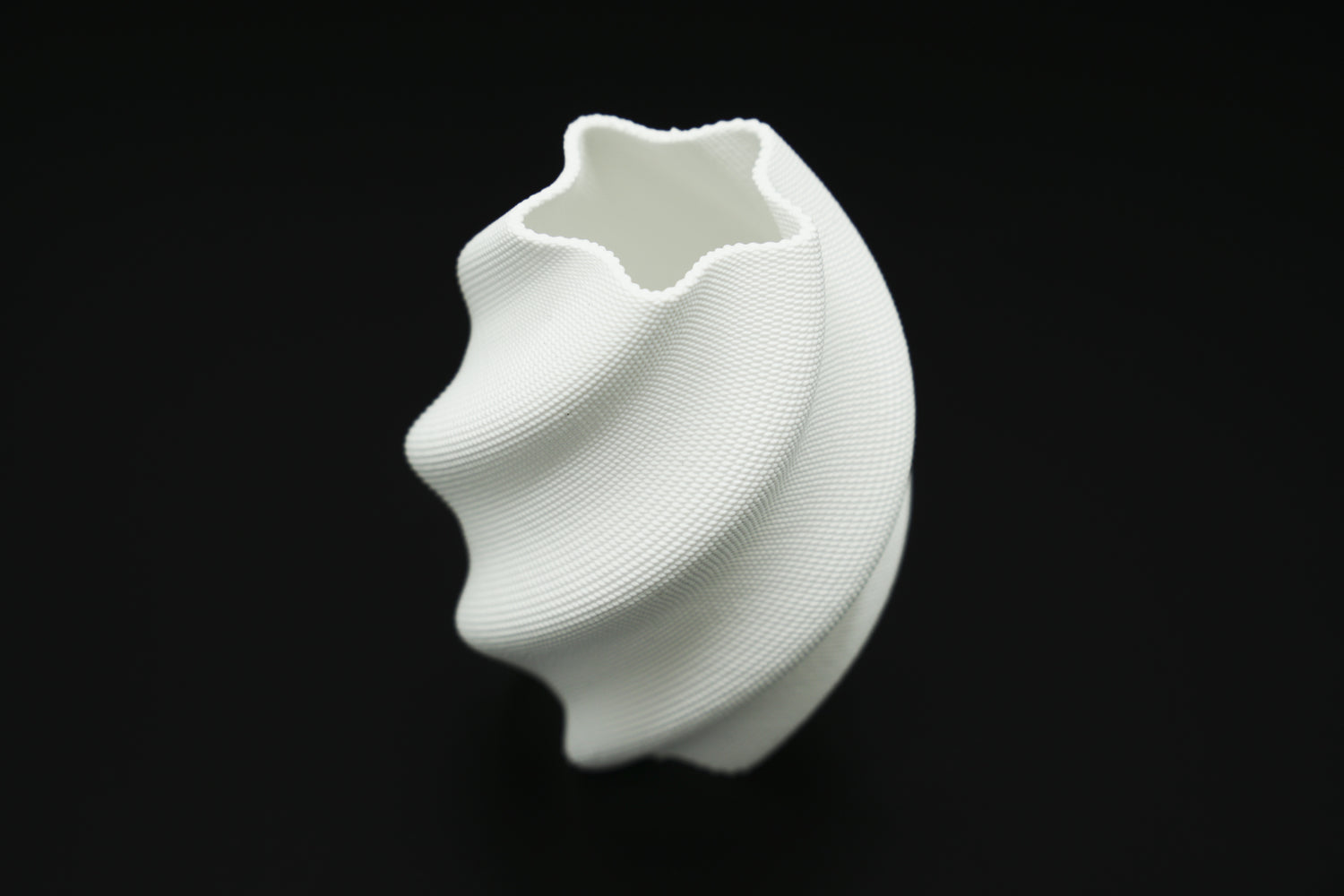

Selective Laser Sintering

A powder-based 3D printing process offering endless design possibilities, post processing, highest quality standards and strength for end-use parts.

Stereolithography

A UV-resin based 3D printing method allowing to produce decorative models with highest level of detail.

Get in touch